Services

Our Services

Contact us today to see how we can help you overcome your automation challenges:

Since our founding in 2005, Fletcher Group Automation has helped bring to production or improve existing lines totaling:

Jump Menu

Engineering

Mechanical Design & Engineering Services

Controls System Electrical Design

Controls System Software Design

Simulations

Field

Controls Integration & Commissioning Support

Robotics Integration & Commissioning Support

Mechanical Design & Engineering

Controls System Electrical Design

Controls System Software Design

Simulations

Field

Other Services

Turnkey Project Services

Value Engineering & Lean Manufacturing

Process Analysis & Improvements

Business Process Automation & Database Development

Controls Integration & Commissioning Support

Robotics Integration & Commissioning Support

Other Services

Turnkey Project Services

Value Engineering & Lean Manufacturing

Process Analysis & Improvements

Business Process Automation & Database Development

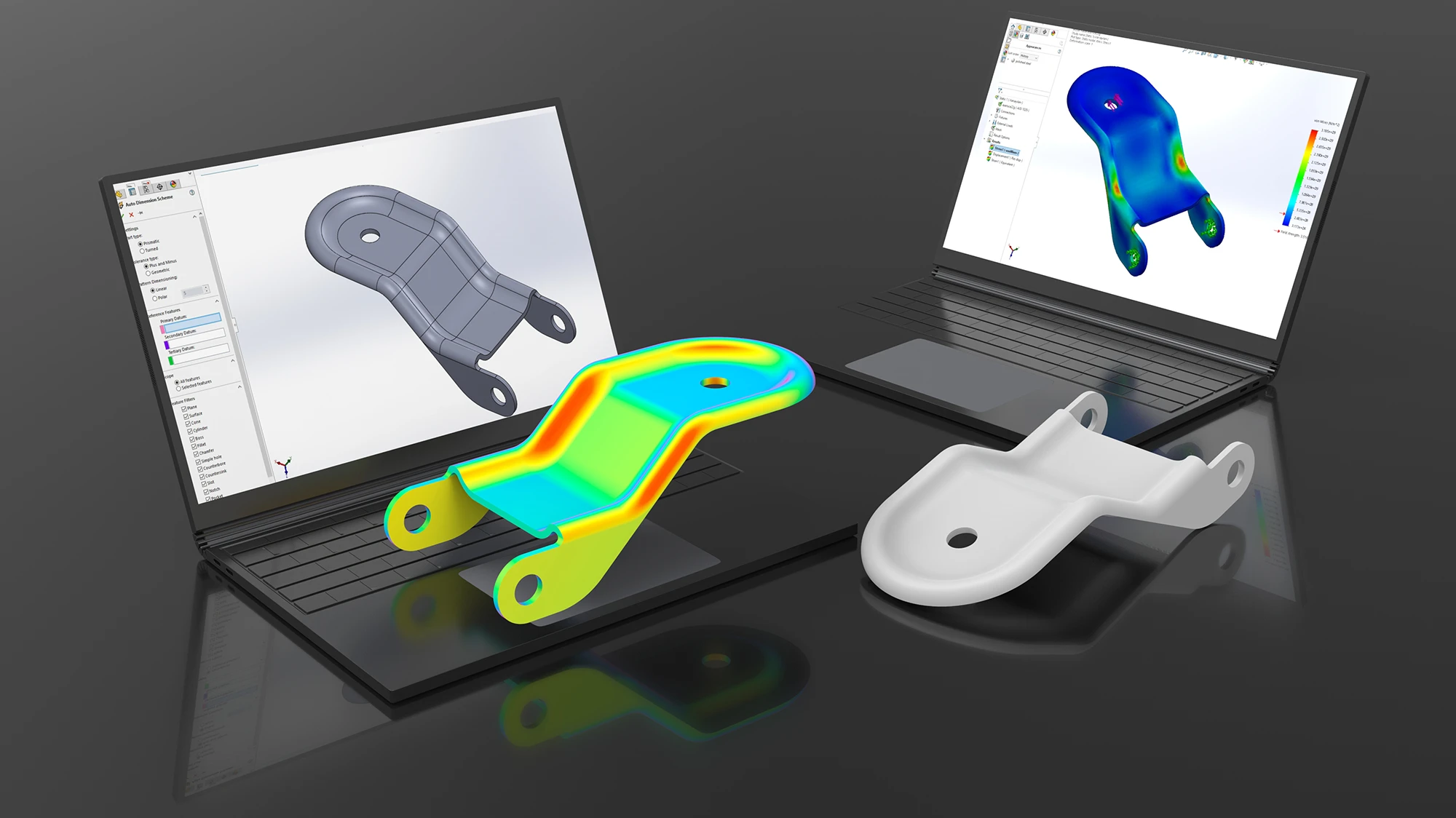

Mechanical Design & Engineering Services

Our Mechanical Design team delivers innovative, efficient, and manufacturable solutions tailored to your project requirements. From concept development to detailed 3D modeling and production-ready drawings, we support every phase of the product lifecycle.

We specialize in:

- Custom machine design

- Tooling and fixture design

- Automated systems and assemblies

- Mechanical component integration

- Reverse engineering

- Design for manufacturability (DFM)

- CAD modeling and detailed documentation (SolidWorks, AutoCAD, CATIA, etc.)

Our engineers work closely with clients to ensure every design meets performance, cost, and timeline goals while aligning with the latest industry standards.

Whether you’re starting from a concept or improving an existing system, we provide the expertise to bring your mechanical designs to life—efficiently and reliably.

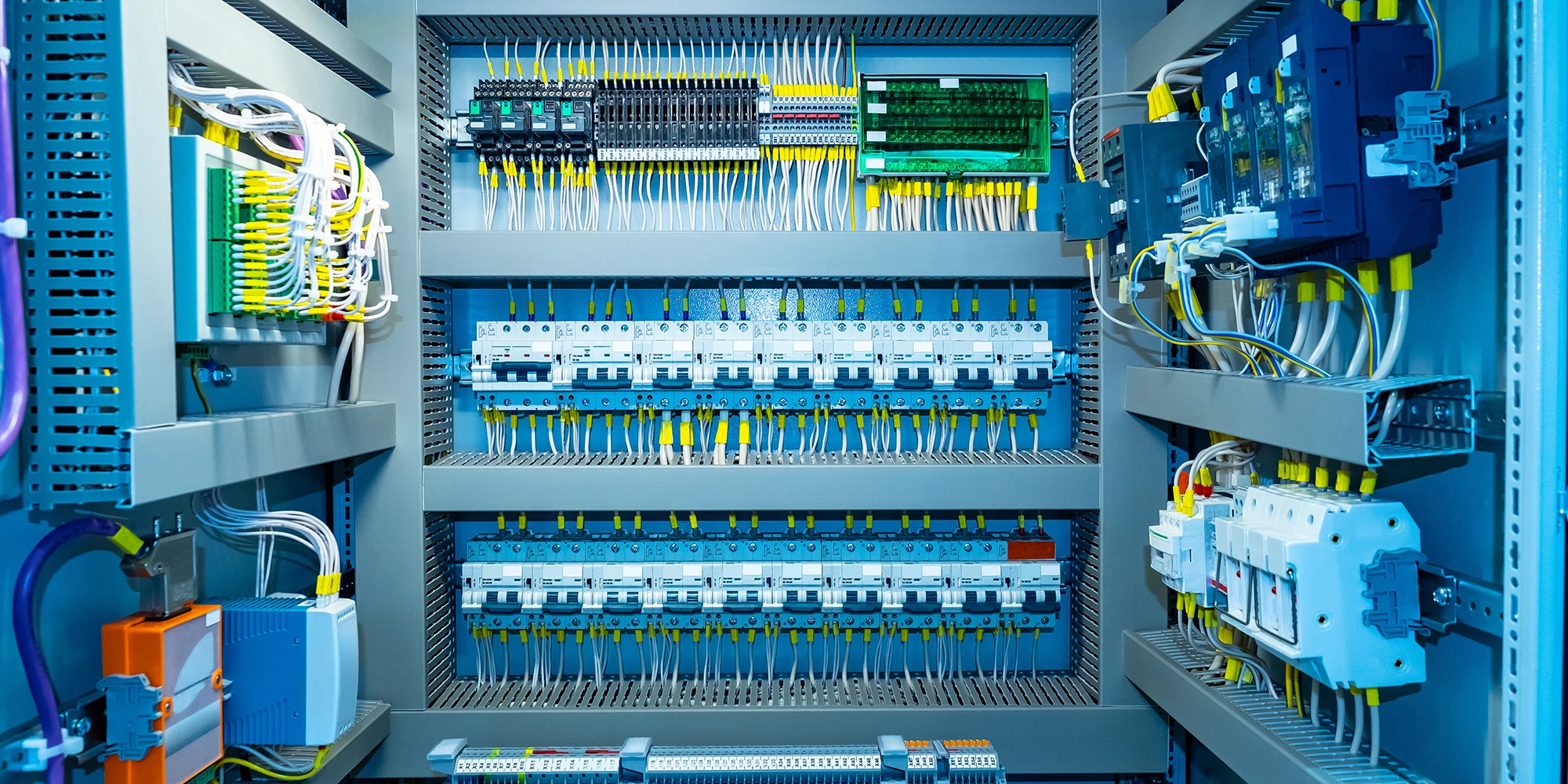

Controls System Electrical Design

We provide full-service electrical design for power distribution and automated control systems, with a focus on reliability, safety, and seamless integration.

Our capabilities include:

- Electrical Panel Design – Power distribution and control systems for industrial automation

- System Integration Design – Specialized in conveyance and material handling applications

- Design Compliance – Adherence to all relevant safety codes and industry standards (e.g., NFPA, UL, CE)

- New & Retrofit Solutions – Design templates and documentation for both greenfield and legacy systems

- Layout Review – Cable routing, tray management, and panel layout optimization.

Using industry-leading platforms such as AutoCAD (ACAD), AutoCAD Electrical (ACADe), EPLAN 2D/3D, and GM EPLAN, we deliver tailored solutions that meet each client’s unique standards, formats, and specification guidelines.

Design Calculations & Sizing:

- Safe distance and safety zone calculations

- Conductor and circuit protection sizing

- Power supply and network switch sizing

- Thermal/heat load calculations

- Pneumatic, gas, and water header/tool sizing

Advanced Control Features:

- Control zones and interlocks

- Safety devices and part sensing

- Stabilizers, pallets, and part tracking

- Barcode and RFID integration for real-time data collection

Deliverables Include:

- Detailed electrical, pneumatic, gas, and water schematics

- Bills of Material (BOMs)

- Comprehensive documentation packages: “As Built” and “As Launched”

Controls System Software Design

Our team provides complete Controls System Design, Virtual Commissioning, Integration, and On-Site Commissioning across diverse industries.

We work within customer specifications to develop reliable, scalable control applications, including:

- PLC & HMI code development with offline validation

- Safety process logic design and implementation

- SCADA and HMI software development and configuration

- Factory Information Systems and tag file management

- Network configuration and communication setups

- Equipment interlocks and safety systems

- Safety placards and identification management

- Comprehensive change documentation and integration checklists

- Virtual commissioning to accelerate deployment and reduce downtime

- System Risk Assessment and mitigation planning

- Onsite field verification and commissioning support

Our expertise spans major platforms such as Allen-Bradley (Rockwell Automation), Siemens S7/WinCC/TIA Portal, as well as RSView, GE Cimplicity, Ignition, and more.

Conveyor Experience Includes:

- Hokuto Power Roller Bed, Lifts, Load/Unload Transfers, and Pivot Tables

- VersaRoll Systems

- Overhead Transfer and Buffer Systems

- Cross-Transfer Conveyors

- Both Operator and Robot Load/Unload Conveyors

- Pallet Design

- Various Brands of VFDs and Servos

Whether deploying new systems or upgrading existing controls, we deliver smooth integration, rigorous testing, and compliant, efficient operation.

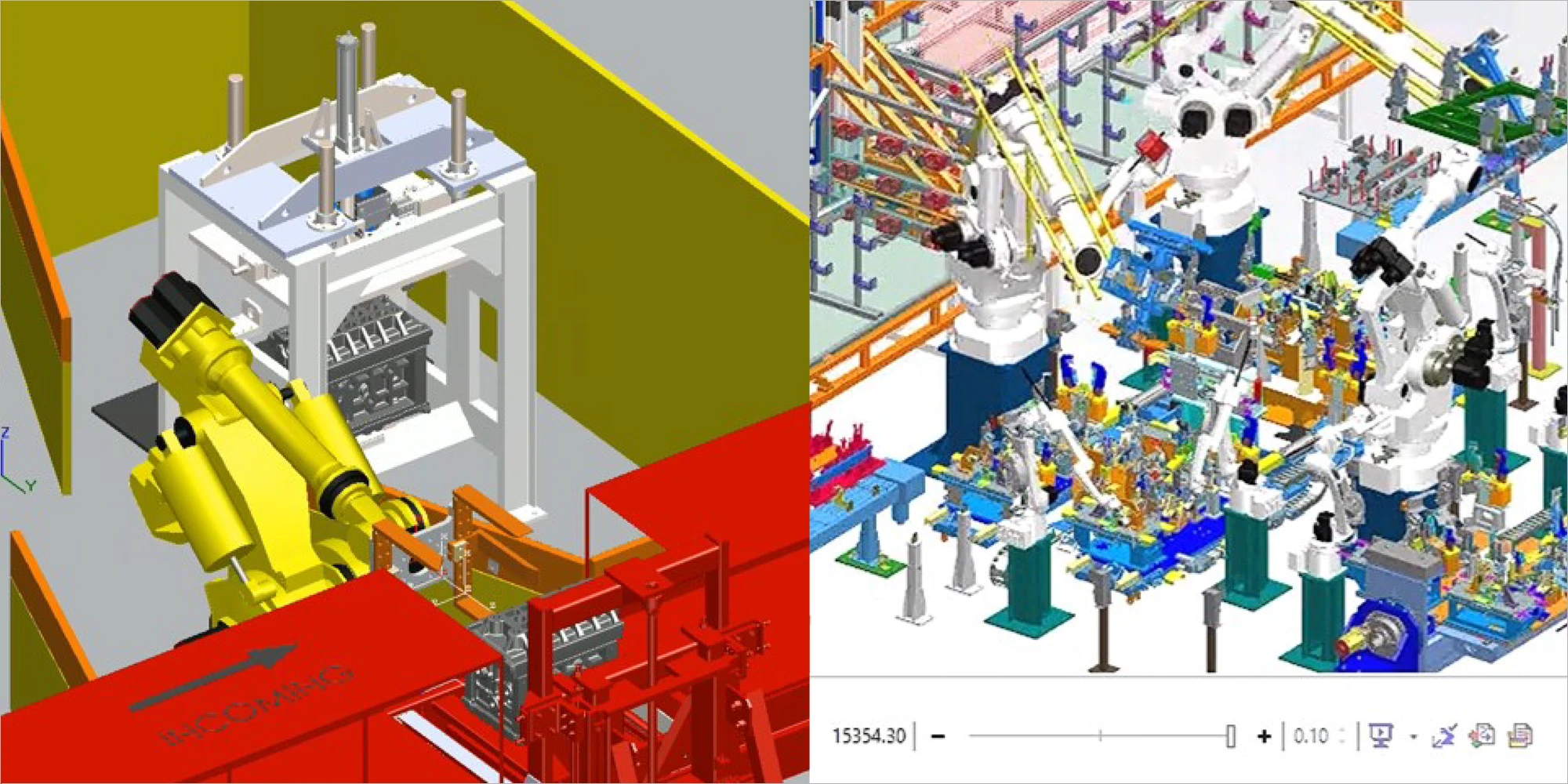

Simulations

Our simulation services enable visualization of robot actions and assembly processes within a 3D virtual environment—often months before physical prototypes are built. These simulations deliver significant time and cost savings by allowing our experts to:

- Identify costly design and programming mistakes before any machine construction begins

- Develop, test, and debug robot programs offline—eliminating the need to interrupt ongoing production lines

- Transfer validated and debugged programs directly to physical robots, streamlining commissioning and installation

We utilize industry-leading simulation and process analysis tools such as Delmia, RobCAD, RoboGuide, and Robot Studio to provide comprehensive throughput analysis and process simulations, ensuring optimized productivity and flawless operation from day one.

Controls Integration

& Commissioning Support

Fletcher Group Automation provides complete Controls and Robotics Commissioning & Support services to ensure systems are deployed safely, debugged thoroughly, and optimized for reliable production.

Our commissioning and support process includes:

- Safety debug

- Network debugging and communication checks

- Full I/O verification

- Control power-on and validation

- Autocycle function testing

- AGV (Automated Guided Vehicle) commissioning support

- ASRS (Automated Storage & Retrieval System) commissioning

- On-site production support

- Manual motion testing

Whether bringing a new system online or supporting an existing installation, our team ensures smooth integration, high performance, and minimal disruption to your operations.

Robotics Integration

& Commissioning Support

Our team delivers end-to-end robotic solutions, from software programming and commissioning to full system integration. We are proficient in virtually every major robot brand, including ABB, Comau, FANUC, Kawasaki, KUKA, Motoman, Nachi, Panasonic, and Staubli—handling everything from stand-alone robot cells to fully integrated plant-wide automation lines.

Applications we specialize in include:

- Cutting

- Laser Brazing

- Sealing / Dispensing

- GMAW / MIG Welding

- Drawn Arc Welding

- Gluing

- Press-to-Press Automation

- Vision-Guided Robotics

Additional services include:

- Vision Systems – Integrated for inspection, guidance, and quality control using leading brands such as Cognex, Keyence, Sick, Perceptron, Izra, Banner, ServoRobot, including advanced Bin Picking with IR Vision 2D & 3D

- Sealers & Adhesives – Automated dispensing and application systems featuring industry-leading equipment including Nordson, Atlas Copco, SCA Shucker, and BMB3

- Plant Maintenance – Preventive and corrective services to maximize uptime and equipment lifespan

- Performance Consulting – Throughput analysis, downtime prediction, and capacity optimization

No matter the size or complexity, we design and implement systems that deliver efficiency, reliability, and long-term value.

Turnkey Project Services

From initial planning through commissioning and post-launch support, our project managers oversee every detail to align with your technical goals, production timelines, and compliance requirements.

Our project management expertise includes:

- Scope definition and requirement gathering

- Budget development and cost tracking

- Timeline and milestone scheduling

- Cross-discipline coordination (controls, electrical, mechanical, software)

- Vendor and contractor management

- Risk identification and mitigation planning

- Regular progress updates and status reporting

- Change management and documentation control

- Resource planning and team leadership

- Site readiness, commissioning, and customer buyoffs

We use proven project delivery frameworks and tools to maintain control, minimize risk, and ensure transparency throughout the lifecycle of your project. Whether managing a stand-alone automation cell or a full plant system, Fletcher Group Automation is your trusted partner for execution excellence.

Value Engineering & Lean Manufacturing

Value engineering isn’t just for manufacturing—it delivers measurable benefits across industries, from healthcare and logistics to government and infrastructure. At Fletcher Group Automation, we apply a structured, creative approach to help organizations improve functionality while minimizing cost across the full project or product lifecycle.

Our multi-disciplinary team collaborates with clients to identify needs, evaluate alternatives, and optimize performance—all while focusing on the best possible return on investment. We also integrate Lean Manufacturing principles to help eliminate waste, streamline operations, and maximize value.

Our value engineering and improvement services include:

- Capital Project Reviews

- Product & Process Improvement

- Project Improvement & Optimization

- Strategic Planning & Feasibility Analysis

- Client and Staff Training

Whether you’re launching a new capital project or refining an existing process, Fletcher Group Automation delivers practical, cost-effective solutions tailored to your goals.

Process Analysis & Improvements

Want to increase reliability, cost savings, and safety?

Our team analyzes clients’ existing processes and provides feedback on the latest industry standards and technologies.

We evaluate key operational metrics, including:

- Process flow charts

- Production mix breakdowns

- Current production rates

- Labor cost breakdowns

- Overall efficiency

- Scrap and rework

- Spaghetti diagrams

- Cycle time analysis

- Lead times

- Product changeovers

- Down time

Our in-depth assessments help identify bottlenecks, reduce waste, and improve throughput, quality, and safety.

Business Process Automation

& Database Development

Fletcher Group Automation doesn’t just specialize in factory automation—we also help organizations streamline their business operations through customized Business Process Automation (BPA) and Database Development solutions.

Our software-driven approach eliminates repetitive manual tasks, improves data accuracy, and enhances collaboration across departments—driving efficiency, speed, and scalability.

We work closely with clients to develop integrated data solutions that:

- Automates repetitive tasks

- Integrates applications

- Enhances communication between departments and systems

We design and implement business process, application, database, and infrastructure automation—regardless of complexity or environment—whether on-premises or in the cloud.

- Enhances communication between departments and systems

Whether your goal is to boost productivity, enable cross-functional collaboration, or reduce time to market, Fletcher Group Automation delivers scalable, custom-built BPA and database solutions tailored to your specific needs.

Everyone Goes Home Safe

Our safety mantra, “Everyone Goes Home Safe,” creates a workplace where everyone takes responsibility for their safety and the safety of those around them. We prioritize a strong safety culture, fostering a secure and productive work environment.